Table of Contents

integrated drive motor (IDM) is a cutting-edge technology that combines the functions of a motor, drive, and controller into a single compact unit. This innovative solution has revolutionized the manufacturing industry by providing enhanced efficiency, precision, and flexibility in various applications.

The Benefits of Integrated Drive Motor

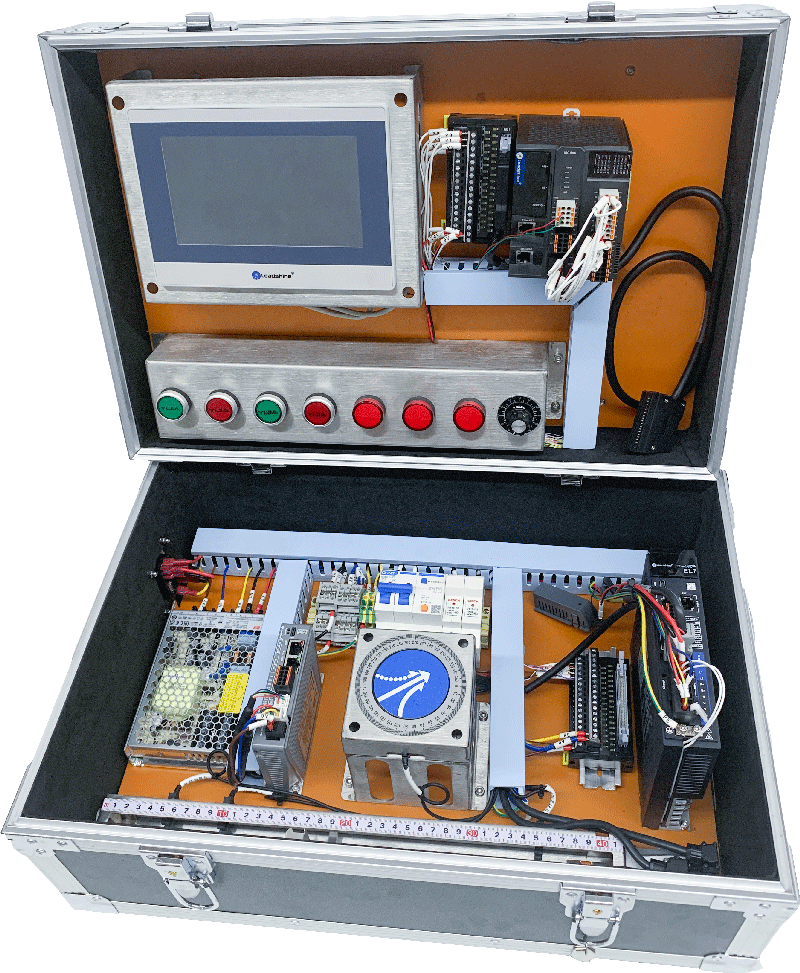

Integrated drive motors offer several advantages over traditional motor systems. Firstly, their compact design allows for space-saving installations in tight spaces or mobile equipment. Secondly, IDM eliminates the need for external wiring and reduces complexity during installation. Additionally, these motors provide seamless integration with other automation components such as sensors and actuators.

Furthermore, integrated drive motors offer improved energy efficiency due to their advanced control algorithms. They can optimize power consumption based on real-time demands, resulting in significant energy savings for manufacturers. Moreover, IDM’s precise motion control capabilities enable high-speed operations while maintaining accuracy and repeatability.

The Innovations by Leadshine

Leadshine is one of the leading companies at the forefront of developing integrated drive motor technology. Their expertise lies in designing highly reliable IDM solutions tailored to meet specific industrial requirements.

Leadshine’s integrated drive motors incorporate state-of-the-art technologies such as advanced microprocessors and digital signal processors (DSPs). These components enable seamless communication between different parts of the system while ensuring precise control over speed, torque, and position.

In addition to their technical advancements, Leadshine also focuses on user-friendly interfaces for easy configuration and monitoring. Their intuitive software allows manufacturers to fine-tune parameters according to their application needs without requiring extensive programming knowledge.

The Role of Motion Control Technology

motion control technology plays a crucial role in maximizing the performance of integrated drive motors. By utilizing advanced algorithms and feedback mechanisms, motion control systems can optimize motor movements, minimize vibrations, and ensure smooth operation.

With the integration of motion control technology into IDM solutions, manufacturers gain enhanced accuracy in positioning and synchronization. This enables them to achieve higher productivity levels while maintaining product quality standards. Additionally, motion control technology allows for seamless coordination between multiple integrated drive motors within a system, facilitating complex manufacturing processes.

The Conclusion

In conclusion, integrated drive motors have revolutionized the manufacturing industry by providing compactness, energy efficiency, precise motion control capabilities, and seamless integration with other automation components. Companies like Leadshine are driving innovation in this field by developing reliable IDM solutions tailored to specific industrial needs. Furthermore, the incorporation of advanced motion control technology enhances the performance of these motors and enables manufacturers to achieve higher productivity levels with improved precision.